Data center Infrastructure Service

FIRE SUPPRESSION SYSTEM

Safe data centers are the indispensable backbone of today’s highly engineered society. They are processing an ever-increasing quantity of videos, voice and data throughout a global network of several billion devices. Applications such as social media, cloud computing, online banking and e-healthcare solutions impact our life every day. In today's world, no one can afford not to be connected. Failure of the internal data center or of the vital data center which serves the general public, poses a significant problem within a short time. Employees who are not able to carry out their work and unhappy customers, who cannot get in touch with their service provider or contractor, represent merely the tip of the iceberg of our technical vulnerability. Therefore, the most important objective in a data center is maximum availability (99.995% per year)1 For maximum protection, a comprehensive fire safety system is needed to ensure business continuity, personal safety and damage mitigation in case of fire. The cornerstones of such a system are a fire detection system that guarantees earliest and most reliable fire detection in a highly ventilated area and that activates the alarming devices, the relevant fire safety controls and appropriate response measures. . It is thus understood that data centers have to be designed, implemented and operated in such a way that a high level of availability can be guaranteed, even in case of a fire. High availability can only be achieved if all relevant influencing factors are planned, implemented and put into effect in the company in a coordinated and consistent

1. FM 200 gas

2. NOVEC 1230 gas

3. IG 55 inert gas

4. IG 100 inert gas

5. Water mist

NOVEC 1230

SEVO Force 500 Systems set the bar by being the first company to design special hazards fire suppression systems with 3M™ Novec™ 1230 Fire Protection Fluid. Other companies using this environmentally sustainable solution only offer 25 bar (360 psi) pre-engineered and engineered systems. We raised the bar by being the only company to offer 34.5 bar (500 psi) systems. More pressure allows retrofit of existing Halon 1301 systems while utilizing welded cylinders.

Our True Retrofit® solution enables you to use existing piping and meet the requirements of industry standards and specifications by simply changing your cylinders and nozzles.

The cylinder valve assemblies are equipped with apressure differential high flow rate valve in order to meet the rapid discharge time of 10 seconds specified in NFPA 2001. Valves are actuated by electric solenoid, pneumatic actuator or manual actuator relieving pressure above the

piston permit the piston to thus fully open the valve and permit the agent to discharge through the valve outlet.

Advantage for 500 PSI

- SMALLER AND/OR FEWER CYLINDERS: REDUCTION IN COSTS

The higher pressure of the FORCE500 system allows the use of smaller cylinder sizes compared to 360 psi systems. In large, multi-cylinder systems, the FORCE500 requires fewer cylinders than the equivalent 360 psi systems due to its added pressure.

FM 200

NAF S 227® is a UL Recognized and US EPA SNAP Listed gaseous extinguishing agent. NAF S 227® Engineered Systems are UL Listed.

NAF S 227® is suitable for use in rooms, vaults, enclosed machines, containers, storage areas and wherever fixed enclosures are present. It is an electrically non-conductive media, it can therefore be used to protect electronic and delicate equipment. After discharge NAF S 227® does not require the clean-up of the protected enclosure, making it extremely useful in applications where damages by other extinguishing methods would be prohibitive.

NAF S 227® has a low order of toxicity. At typical design concentrations it can be safely used to protect normally occupied areas.

Its formulation includes a patented additive that reduces the levels of decomposition by-products normally generated by halocarbons during extinguishment and enhances extinguishing performance (inter alia US Patent No. 6,402,975 and EU Patent No. 630,278)

INERT GAS

SEVO ecoINERT™ is a clean agent fire extinguishing system using inert gas (IG55, IG541, IG100 or IG01) and is used in total flooding systems.

SEVO ecoINERT™ has become widely accepted as the best performing, most cost effective, and environmentally friendly inert gaseous suppression system, offering extended hold times and great flexibility in design.

SEVO ecoINERT™ is an ideal choice for a wide variety of industries and applications, suitable for facilities such as computer rooms / data centres, telecommunications facilities, and the like. SEVO ecoINERT™ is unique in that it utilises a pressure regulating discharge valve which produces lower discharge pressures which also translates into lower costs all around, resulting in savings with pipe work, venting area and cylinder storage

RACK MOUNT

SEVO Cube, The rack mounted automatic fire suppression unit from SEVO Cube provides protection for electronic equipment stored in rack enclosures and cabinets. Designed for 19" racking systems, the suppression unit is self-contained and has built-in fire detection sensors. In the event of a fire, the detectors are activated and the suppression unit is automatically triggered to release the extinguishing gas. SEVO Cube responds to a detected fire condition within 10 seconds of activation. The NOVEC 1230 extinguishing gas is non-ozone depleting and has proven to be safe and reliable without causing damage to electronic equipment.

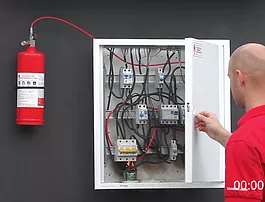

MDB-CABINET

The SEVO™ Flex™ utilizing 3M™ Novec™ 1230 Fire Protection Fluid offers the unprecedented flexibility of providing localized protection of high value equipment for maximum efficiency and cost effectiveness.

SEVO™ Flex™ is designed to meet the rapid discharge time (up to 10 seconds)in accordance with NFPA 2001. Multi-Point provides partial/local flooding of a single or multiple hazards.

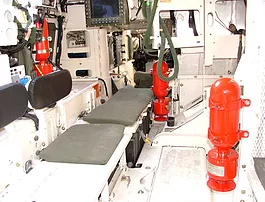

Military Vehicle Explosion

SPECTREX, Troops rely on their confidence in the fire protection system to stay inside the vehicle when combat occurs. A fire inside an armoured fighting vehicle caused by enemy fire can rapidly grow to engulf areas that are covered with fuel and produce high intensity heat radiation, smoke and the risk of an internal explosion. Our Automatic Fire Extinguishing System (AFES) detects fires and explosions, including ‘slow growth’ fires and will automatically initiate the high speed suppression system to extinguish the fire or explosion and provide survivability for the personnel within the vehicle. Engine bay systems are also available to rapidly detect and extinguish any fires that may occur as a result of overheating in combat or from enemy fire.

Low Pressure Water Mist

The International Fog Inc (IFI) Deluge-Tech nozzles use patented IFI fog and rotor technology and are designed to control and suppress fires. IFI Deluge-Tech nozzles are installed on fixed fire protection systems. The nozzles are designed to apply cooling water to exposed vertical, horizontal, curved and irregular shaped surfaces to protect objects from adjacent fires as well as to control or extinguish fire within a protected hazard area. The IFI Deluge-Tech RC150A Nozzle has a rotor that improves water droplet momentum and distribution, making it a more effective suppression nozzle than conventional deluge nozzles with deflector plates. The water is simultaneously directed at a wide angle, providing a protective water curtain, as well as forward which allows for greater reach. The nozzle is used in applications where deluge water spray systems are installed for special hazards protection. The IFI nozzle produces superior protection with a minimum water pressure of 50 psi to a maximum pressure of 175 psi. The nozzle may be oriented in any direction necessary to protect the hazard.